Call us now

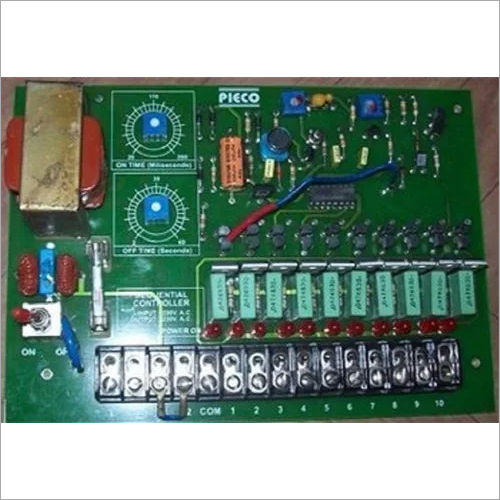

08071931155Sequential Timer Card

2900 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 2-3 Days

Voltage 12 Volt (v)

Usage Industrial

Type Hardware Timers

Theory Electronic

Operating Temperature 0-55 Celsius (oC)

Material Plastic

Color Green

Supply Ability 8000 Per Month

Main Domestic Market All India

About this product

A technological tool called the Sequential Timer Card is intended to automate time sequences in a range of applications. Up to eight separate output channels can be set to be under its control, and each one has a delay time and duration that can be adjusted. The card has a user-friendly interface with LED indicators for each channel and runs on a low voltage DC power source. The Sequential Timer Card is the perfect option for managing and coordinating automated processes in commercial, scientific, and industrial environments thanks to its precise timing capabilities and small size.

| Relay Type | Time Card |

Efficient Timing for Industrial Automation

The Sequential Timer Card is built to streamline industrial processes through accurate and sequential time control. Its durable plastic material combined with a wide operating temperature range means it can withstand harsh operational conditions, ensuring minimal downtime and long-term reliability. Integration into existing systems is straightforward, enabling effective automation and efficiency improvements in production lines and similar settings.

Robust Design with Simple Installation

Engineered for easy installation in industrial environments, the Sequential Timer Card utilizes straightforward electronic theory for dependable hardware operations. The card's green plastic construction not only gives it a distinctive appearance but also ensures protection against typical factory pollutants. Its 12V power requirement matches standard industrial power sources, simplifying compatibility and replacement procedures.

FAQ's of Sequential Timer Card:

Q: How is the Sequential Timer Card used in industrial applications?

A: The Sequential Timer Card is implemented to control the timing and sequence of operations in industrial machinery. It can automate tasks such as conveyor movement, process cycles, or other repetitive actions by ensuring each step occurs in a predetermined order and duration.Q: What is the process for installing the Sequential Timer Card?

A: Installation involves connecting the card to a suitable 12V power supply and integrating it with the timing circuit or control panel. Detailed wiring diagrams are typically provided to guide users through the process, ensuring safe and efficient setup.Q: When should the Sequential Timer Card be used?

A: This timer card is ideal when precise timing control and sequencing are necessary, particularly for automated processes in manufacturing or industrial settings. It is especially useful for repetitive sequences or multiple device timing in assembly lines.Q: Where can the Sequential Timer Card be installed?

A: The card can be housed within control cabinets or directly into machinery enclosures in environments where ambient temperature ranges from 0 to 55C. Its robust plastic design makes it suitable for most industrial locations.Q: What are the main benefits of using this Sequential Timer Card?

A: Users benefit from easy integration, reliable performance, and improved process efficiency. The card reduces manual intervention by automating sequences, lowering operational errors, and optimizing workflow timing.Q: How does the operating temperature range affect its usage?

A: With a range of 0-55C, the card is suited for most indoor industrial settings. Operating outside this range is not recommended, as extreme temperatures may affect electronic stability and performance.Explore Additional Categories

Contact Us

Our Products

Our Products