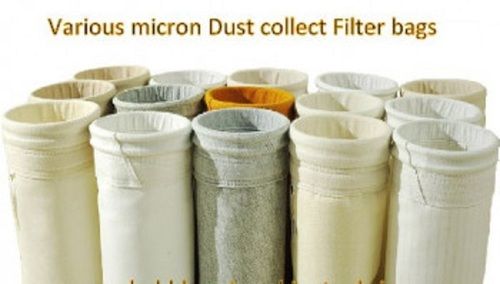

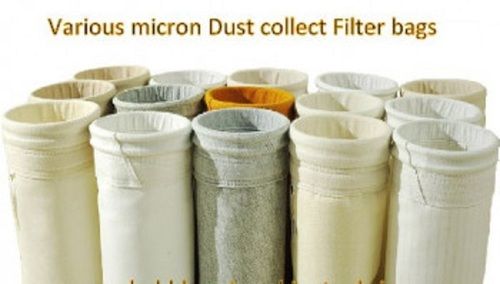

They are perfect for settings where electrostatic discharge (ESD) is a concern because they are comprised of specialist materials that offer filtration and ESD protection. Excellent durability and resistance to mechanical stress, high temperatures, and chemical corrosion are both features of these bags. The risk of sparks or exploosions is decreased thanks to the special antistatic qualities of these filter bags, which work to prevent the accumulation of static electricity. Antistatic filter bags are crucial for sectors including pharmaceutical, food and beverage, and chemical processing where rigorous standards of hygiene and safety must be upheld due to their dependable and effective performance.

Features of Antistatic Filter Bag:

- Highly efficient

- Highly popular

- High performance

- High efficiency

- Used in various treatments

- Meet industry norms

- Durable

High-Efficiency FiltrationWith a filtration efficiency of 95%, the Antistatic Filter Bag effectively captures fine particulates, helping maintain cleaner and safer industrial workspaces. Its advanced polyester construction ensures minimal airflow resistance while delivering superior dust retention. This optimal blend of material and design is ideal for industries where air quality and static management are crucial.

Versatile Industrial ApplicationsCustom size options make this filter bag excellent for various industrial applications. From process protection in manufacturing to use in pharmaceuticals and chemical plants, the antistatic properties minimize the risk of static discharge, safeguarding sensitive machinery and improving overall workplace safety.

Durable and Adaptable DesignConstructed to withstand temperatures between 0 and 80C, the polyester Antistatic Filter Bag demonstrates exceptional durability and thermal stability. Its robust structure and tailored sizing cater to specific industrial requirements, ensuring a long service life and reliable performance even in demanding conditions.

FAQ's of Antistatic Filter Bag:

Q: How does the Antistatic Filter Bag function in industrial environments?

A: The Antistatic Filter Bag uses polyester material to filter out up to 95% of airborne particles while its antistatic properties prevent static electricity buildup, ensuring a safer and cleaner work setting in various industrial applications.

Q: What are the benefits of using a polyester antistatic filter bag?

A: Polyester offers excellent filtration performance, durability, and chemical resistance. The antistatic treatment adds an additional layer of protection by eliminating issues related to static discharge, reducing the risk of ignition and protecting sensitive equipment.

Q: When should this filter bag be replaced in an industrial setup?

A: Replacement is recommended when there is a noticeable drop in filtration efficiency, increased pressure drop across the filter, or visible damage. Maintenance schedules may vary depending on the dust load and operational conditions.

Q: Where can I use the Antistatic Filter Bag?

A: This filter bag is suitable for use in a wide range of industries, including manufacturing, pharmaceuticals, chemicals, and other sectors where dust control and static management are necessary for process protection.

Q: What is the process for customizing the filter bag size?

A: You can provide your specific size requirements to the manufacturer, supplier, or trader based in India, who will then fabricate the filter bag in accordance with your equipment dimensions and operational needs.

Q: How do I install and use the Antistatic Filter Bag?

A: Installation involves fitting the customized bag into your dust collection or filtration system according to manufacturer guidelines. Regular inspection and timely replacement ensure optimal performance and safety.

Q: What makes this filter bag a reliable choice for industrial protection?

A: Its 95% filtration efficiency, antistatic properties, temperature resilience (0-80C), and customizable sizing make it particularly reliable for managing airborne contaminants and static in dynamic industrial settings.